Stainless Steel Welded Pipes & Tubes division consist of:

- Tube Mills

- Bead Removing Machines

- Cold Drawing Benches

- ‘U’ Bending Machine

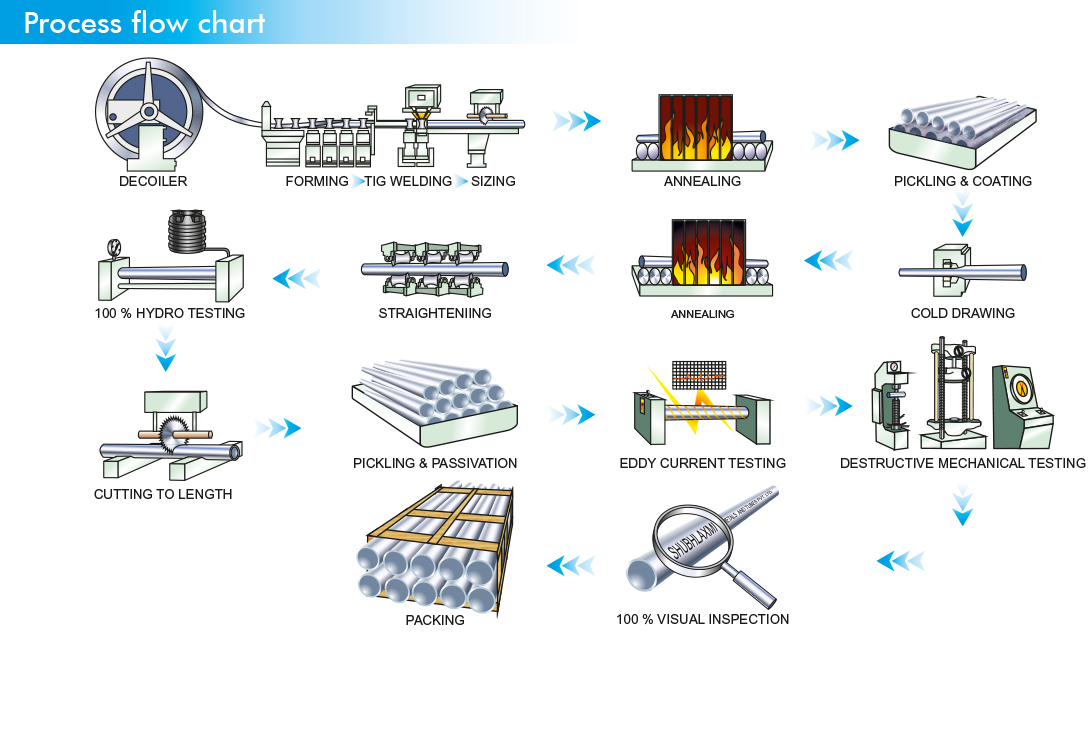

This division also has Roller Hearth Heat Treatment Furnaces to conduct solution annealing for tube finishing lines including pickling, tube straightening, end facing, and cut-to-length facilities. We also conduct various destructive and non-destructive tests to produce high quality products that conform to international standards.

These facilities are capable of manufacturing 3000 tonnes of Stainless Steel Welded Pipes & Tubes of various Austenitic Ferritic & Duplex Steel per annum.

| PRODUCT | SIZE | THICKNESS | SPECIFICATION |

|---|---|---|---|

| PIPES | 1/8” NB TO 14” NB 8” NB to 64” NB |

Sch.5, 10, 40s 3.00mm TO 30.00mm |

ASTM A-312,A-358, A-554, A-778, A-409, A-790 & Its Equivalent ASME, DIN & EN Standard |

| TUBES | 6.35 mm To 102 mm OD | 0.50 mm TO 7.0 mm | ASTM A-249, A-268, A-269, A-270, A-554, A-688, A-778, IS 13316:92, EN 10217-7 & Its Equivalent ASME, DIN & EN Standard |

AUSTENITIC GRADES: 304/L/H/LN, 316/L/H/LN/Ti, 317L, 321/H, 347/H, 309, 310/S, and 904L.

FERRITIC & MARTENSITIC GRADES: 409/L/M, 410, 430/Ti, 436, 439, and 441.

DUPLEX STAINLESS STEEL: UNS 31803, 32205, 32750, and 31500.

LENGTH: As per customer requirement (up to a maximum of 22 meters)

FINISHING: Tubes can be supplied with mirror and mechanical polishing with grit ranges of 80, 120, 240, 320, 400, 600, and more.